Kaizen is one of the approaches to improving the organization work. This term appeared in Japan and began to mean an

interrelated actions system that can to lead to an improvement in the quality of products, processes and management systems.

Kaizen (in the modern sense) is a system of continuous improvement of quality, technologies, processes, corporate culture, labor

productivity, reliability, leadership and other aspects of the company's activities.

The main focus of the Kaizen system is on the "quality" of the staff, because the quality of products and services

depends on the staff. This system involves every employee in the process of improvement - from the top management, to an ordinary

employee.

Each organization employee offers small improvements on a regular basis. Suggestions are made not sporadically, but constantly.

They are not global in nature for the most part, but are minor improvements. This is the essence of the Kaizen system - a large

number of small, insignificant improvements leads to a serious quality improvement.

Suggestions for improvement may not be limited to a specific area, for example, production or marketing. Kaizen is based on

making changes wherever it can be made improvements.

Kaizen elements

The kaizen system is based on 5 key elements. It is necessary to create conditions for their implementation in organization, in

order it to work normally and be an effective quality improvement tool.

- The first element is teamwork. All employees should work as a one team to achieve a common goal and the desired improvement

in work. Employees at all levels of organization should do everything for the benefit of their colleagues and the company.

Teamwork means a regular information exchange, mutual training, timely performance of their duties, and so on.

- The second element is personal discipline. Discipline is the major importance for success. The Kaizen system requires

increasing self-discipline from every employee in all aspects of work Ц time management, the quality of work, compliance with

requirements and regulations, expenditure material and financial resources, etc.

- The third element is the morale. The staff should attempt to maintain high morale despite of the company can succeed in

implementing the changes or cannot. Top management should implement various motivational tools into the practice of work, such

as good working conditions, merits, a system of incentives and rewards, paid leave, benefits, payment of medical services,

loans provision to employees, etc.

- The fourth element is quality circles. This is one of the fundamental elements of the kaizen system. It is necessary to

establish the work of quality circles in the organization. These circles should include employees from different organizational

levels. Employees have the opportunity in quality circles to exchange ideas, skills, technologies and other resources important

for collaboration. Information exchange and interaction within the quality circles allows employees to evaluate the

effectiveness of their work based on comparison with the work of other peoples. Employees can improve their activities due to

this.

- The fifth element is suggestions for improvement. It is necessary to give employees the opportunity to freely offer

improvements regardless of the rank occupied in the management system. Employees' suggestions can be anything, even absurd,

and all of them should be taken into account and considered.

Kaizen Principles

The Kaizen system implementation in practice implies following the basic principles of this system:

- workplace organization;

- elimination of unnecessary losses;

- standardization.

1. Workplace organization is workplace management in order to optimize activities. Kaizen system pays a lot

of attention to this. This process is named the term "gemba" in the Japanese version. Appropriate management tools

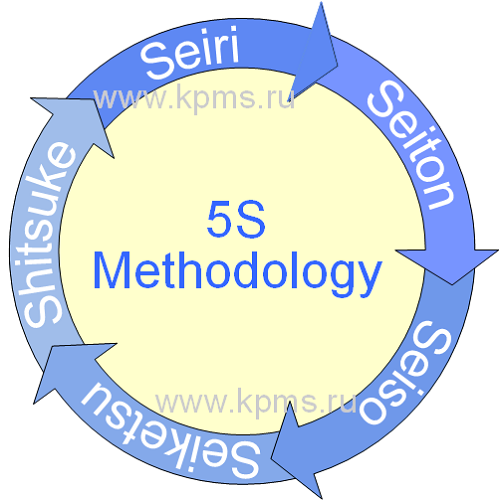

are used for the correct organization of the workplace. These tools are called the У5SФ methodology. The У5SФ term comes from

the first letters of Japanese words.

The structure of the У5SФ methodology actions includes:

- Seiri - it is necessary to sort out items that are not required in the work. Special marking can be used to identify

unnecessary elements. If the identified elements are not in demand by anyone, then they are removed from the workplace.

- Seiton - it is necessary to arrange everything that is required in the work. These elements should be in view. Tools

and devices should be located in places where they are easy to detect.

- Seiso - a workplace and all equipment must be clean. The workplace should be cleaned, and all tools and equipment put in

their places after the end of the working day.

- Seiketsu Ц it is standardization of the first three steps. These actions should become a daily practice of work. It is

necessary to conduct training with employees on the implementation of these actions when they see improvements from the correct

organization of the workplace.

- Shitsuke Ц it is maintaining an established workplace management practice. It is necessary to create a system of supervision

and monitoring of the organized and standardized workplaces content.

2. Elimination of unreasonable losses - this is the process of finding and eliminating actions that do not add

value. This process is called "muda" in the Japanese version. Most of the works are a sequence of actions that transform

the source material into the product. Some of these actions add value to the product, and some do not add. The part that does not

add value is a loss and must be eliminated.

The kaizen system is considered seven types of losses or seven "muda":

- Motion - unproductive and unnecessary motions increase the execution time of operations and their complexity.

- Waiting - excessive waiting time for the execution of operations leads to an increase of the production cycle.

- Technology - incorrectly organized process technology leads to inconsistency of actions.

- Transportation Ц long distances, moving from place to place, lifting and lowering during the production process increase

non-production costs.

- Defects Ц the correction of defects takes the cost of materials and labor.

- Stocks - excess stocks of materials add cost to products, but do not give value.

- Overproduction Ц more products were produced than planned.

3. Standardization - It is the process of standardization of work. Standardization creates the basis for stable

operation, but standards should be changed when the external and internal environment changes both. The standardization process is

never completed in the Kaizen system. Standards are continuously being improved. The improvement of standards is carried out

according to the PDCA cycle.

Kaizen implementation

The use of the kaizen system is carried out through the creation and continuous operation of the Kaizen teams.

There are five main types of commands:

- Regular teams Ц these teams work every day. These teams include specialists (workers, employees) who perform onsite work.

- Problem solving teams - these teams are formed to find solutions to a specific problem at work. The teams consist of members

from several regular teams. The total number of participants in one team is from six to eight people, as a rule. The team

disbanded after making a decision.

- Cross-functional teams - they are formed to evaluate the existing processes of the organization and search for opportunities

to improve them. The teams consist of ordinary specialists and managers from various departments.

- Solution Implementation teams - they are formed to implement the developed process improvements. These teams are formed from

members of regular teams, problem solving teams, and cross-functional teams.

- Small groups - they are formed for the development, implementation and application of specific or new processes. The teams

include lower level specialists (workers, employees) and department heads from regular teams and teams to solve problems.

The work of the teams (with the exception of regular ones) is carried out during Kaizen sessions. The kaizen sessions duration

is from 2 to 5 days. Each session is aimed at solving a specific business problem. The organization of work within the kaizen

session is based on the PDCA cycle principle.